With the rapid advancement of technology, semiconductor automation has emerged as a game-changer in the manufacturing industry. This article explores the various aspects of semiconductor automation and its impact on efficiency and productivity.

The Role of Semiconductor Automation

Semiconductor automation refers to the use of advanced technologies and systems to automate processes involved in semiconductor manufacturing. It encompasses a wide range of applications, including robotics, artificial intelligence, machine learning, and data analytics.

By implementing semiconductor automation solutions, manufacturers can streamline their production processes, reduce human error, enhance product quality, and increase overall operational efficiency. These advancements have revolutionized the industry by enabling faster production cycles and reducing costs.

The Rise of Mobile Robot Systems

One significant aspect of semiconductor automation is the integration of mobile robot systems into manufacturing facilities. These robots are equipped with sensors and navigation capabilities that allow them to perform tasks autonomously within a controlled environment.

Mobile robot systems play a crucial role in automating material handling operations such as transporting raw materials or finished products between different stages of production. They can navigate through complex layouts efficiently while ensuring safety measures are followed at all times.

This integration not only reduces manual labor but also minimizes errors caused by human intervention. With increased precision and reliability offered by mobile robot systems, manufacturers can achieve higher throughput rates while maintaining consistent product quality.

Youibot: A Pioneer in Semiconductor Automation

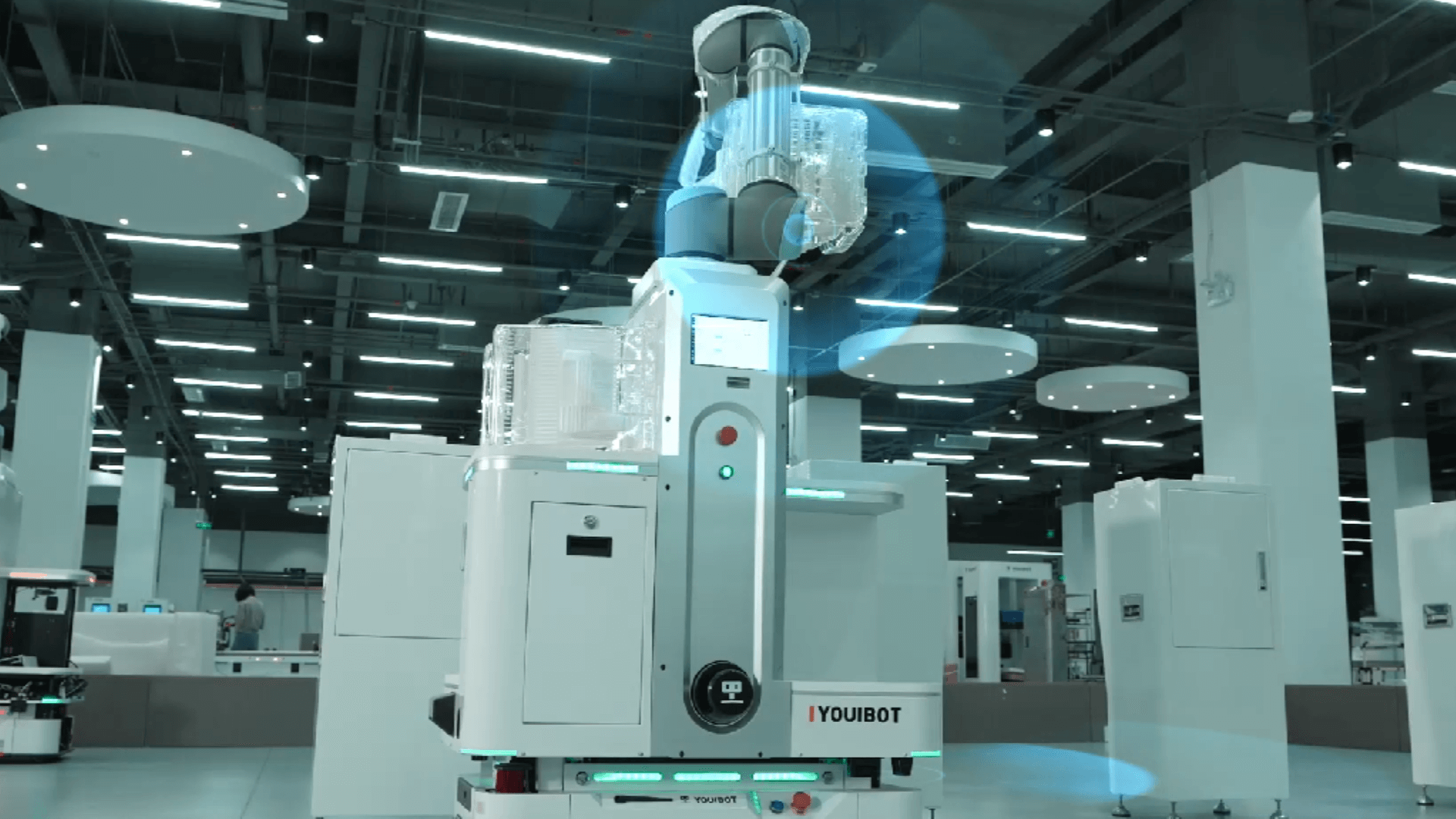

Youibot is one prominent player in the field of semiconductor automation solutions. The company specializes in developing intelligent robotic platforms specifically designed for industrial environments.

Their robots combine state-of-the-art technologies like computer vision, deep learning algorithms, and collaborative features to provide efficient solutions for various manufacturing processes. Youibot’s robots can perform tasks such as material handling, assembly, and inspection with high accuracy and speed.

By leveraging the capabilities of Youibot’s robotic systems, manufacturers can optimize their production lines, reduce downtime, and improve overall productivity. These advancements contribute to the growth of semiconductor automation in Missouri and beyond.

In Conclusion

Semiconductor automation has revolutionized the manufacturing industry by introducing advanced technologies like mobile robot systems. The integration of these systems enhances efficiency, reduces errors, and improves overall productivity in semiconductor manufacturing processes.

Youibot’s contribution to semiconductor automation further strengthens its impact on industrial operations. As technology continues to advance rapidly, we can expect even more innovative solutions that will shape the future of semiconductor manufacturing in Missouri and worldwide.